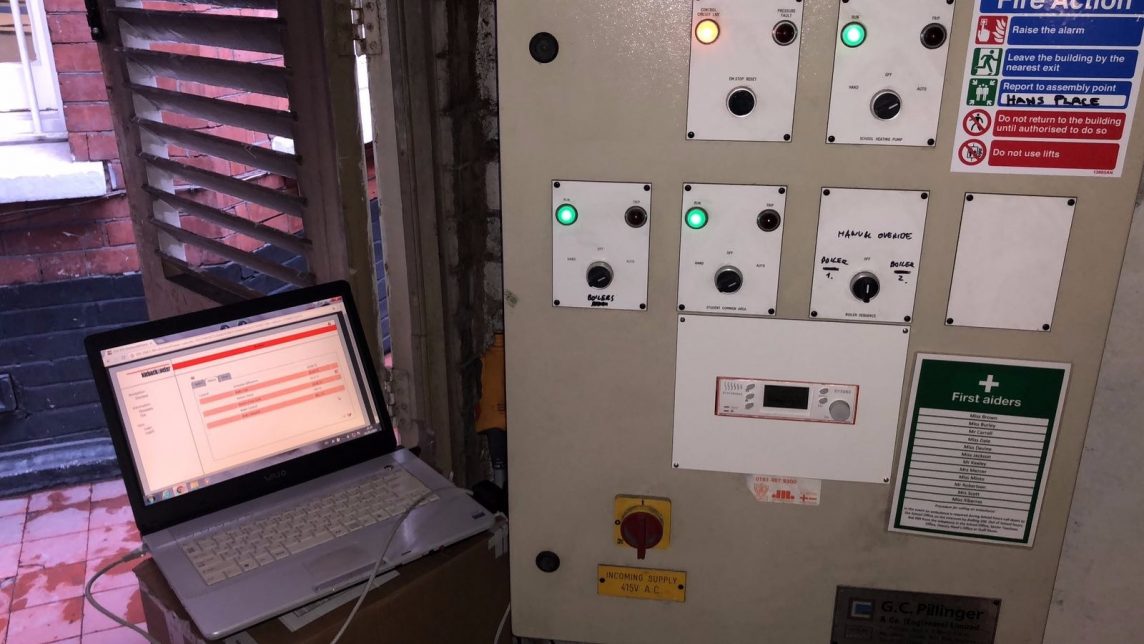

Sometimes the notebook is the needed tool for the job.

Recent Posts by Bonus Eventus

Boiler’s plastic condensate pipe connected into copper pipe.

The acidic condensate water will cause a leak on the copper pipe, signs already visible.

Commercial kitchen extractor fans

Nobody would like to have guests who got sick due to the unhygienic circumstances.

The ventilation is often a part of a kitchen which is thought to be not so important.

The extraction hood above the appliances leads to fans and the extracted vapor grease and fat flows thru these.

This is how it looks like on the inside without maintenance. It’s covered with fat extracted thru the hood.

This can shorten its lifetime and can cause damage to it which leads to expensive repairs.

Maintenance is always cheaper than repair.

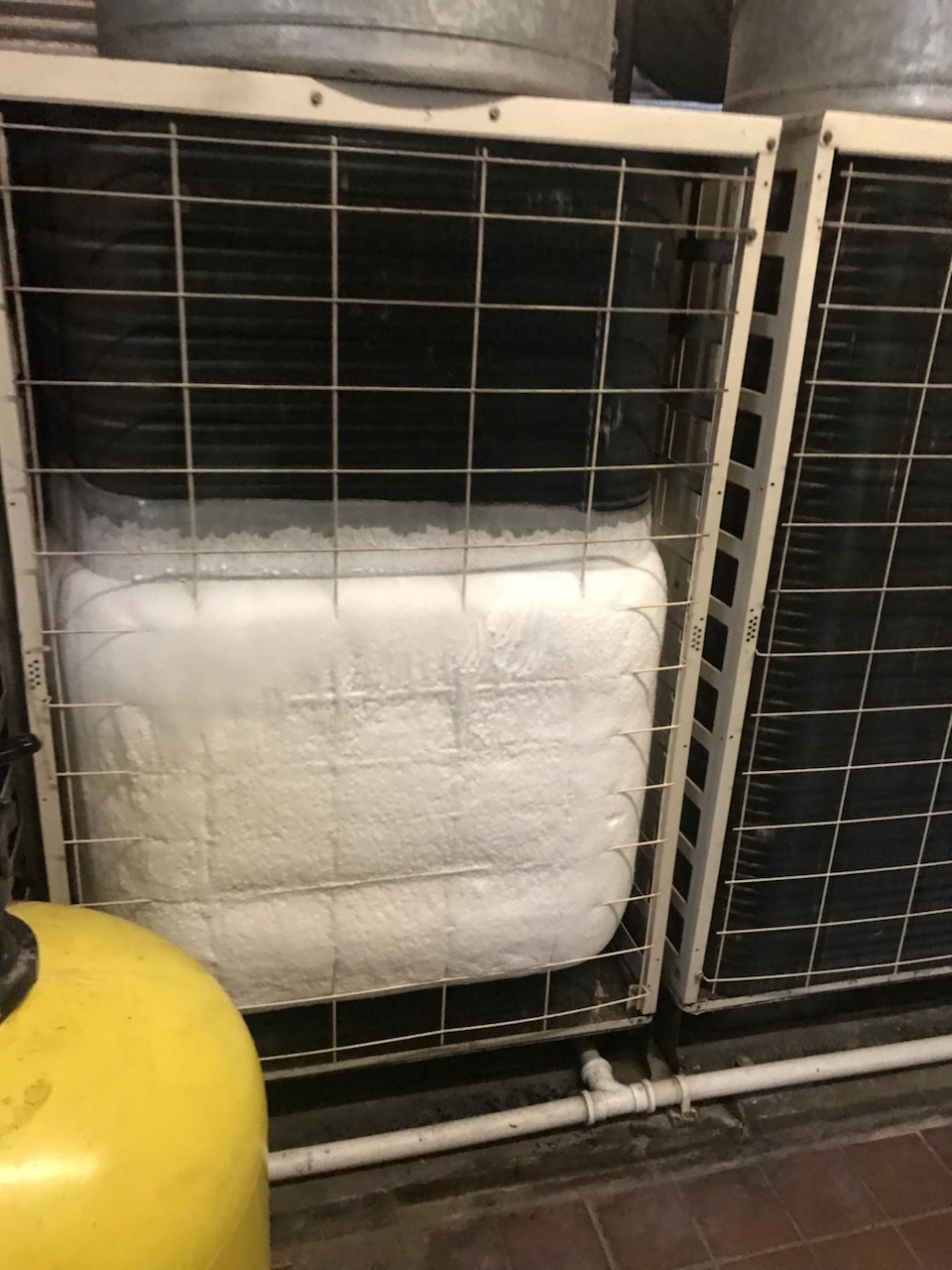

Loft water tanks

Why is it important to regularly check, maintain and clean the water tanks?

That’s why.

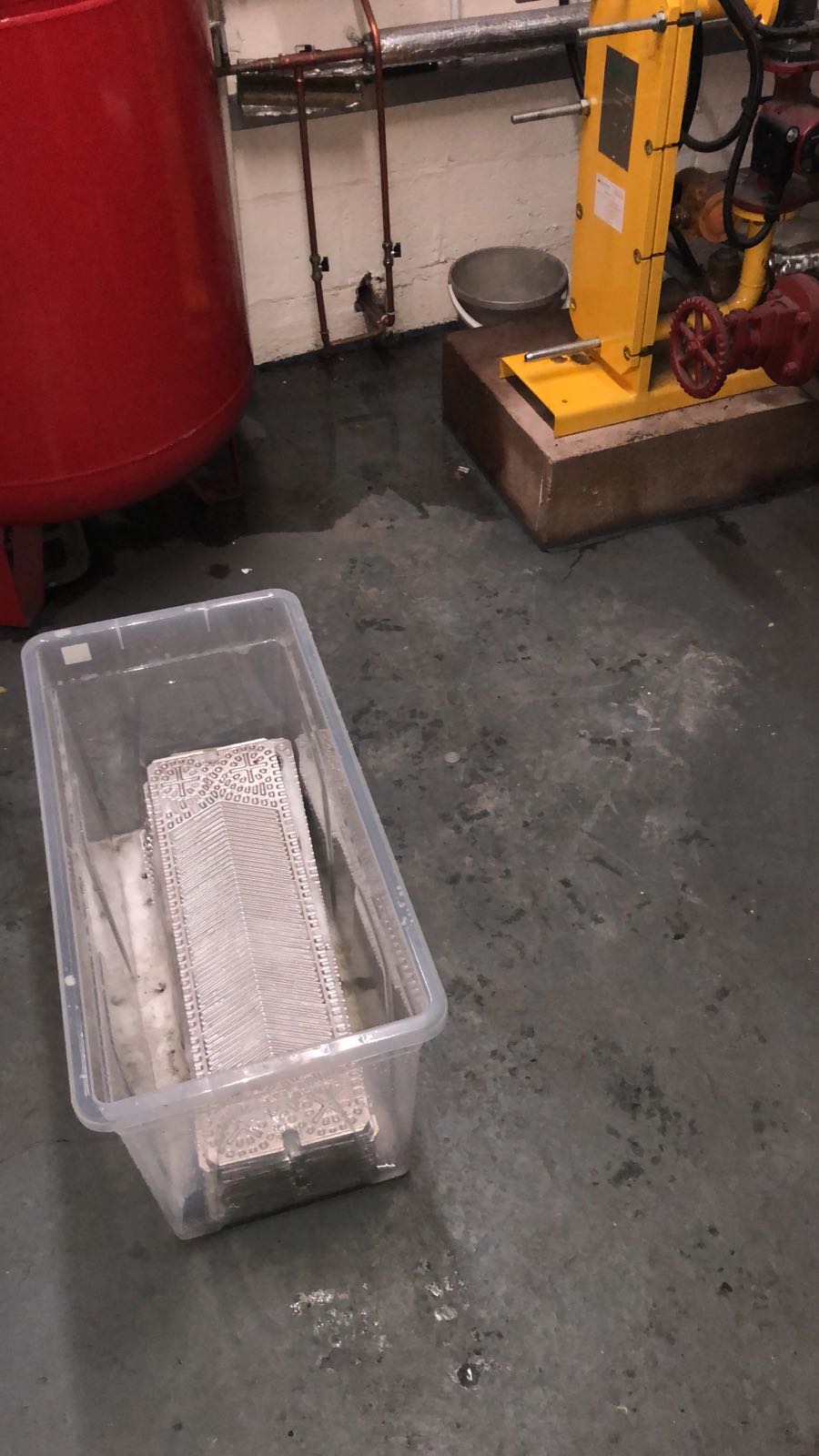

Heat Interface Units (HIU)

Almost like a boiler but it does not use the heat of burning gas directly but the heat of the hot water from the central boiler. This one has a broken actuator and the tenant was left without hot water. As in most of the cases this fault could have been prevented. The blue scale marks on the valve were visible before the actuator got broken and they mean an issue with the valve. During a maintenance visit the early sign of breakdown of the valve would have been spotted. unfortunately, there was no maintenance made on this hence the issue got worse and the valve got stuck and broke the actuator.

The HIUs are just as important parts of a heating system as a boiler and as such they need to be checked, maintained at least annually, preferably quarterly as they are providing the hot water as well.